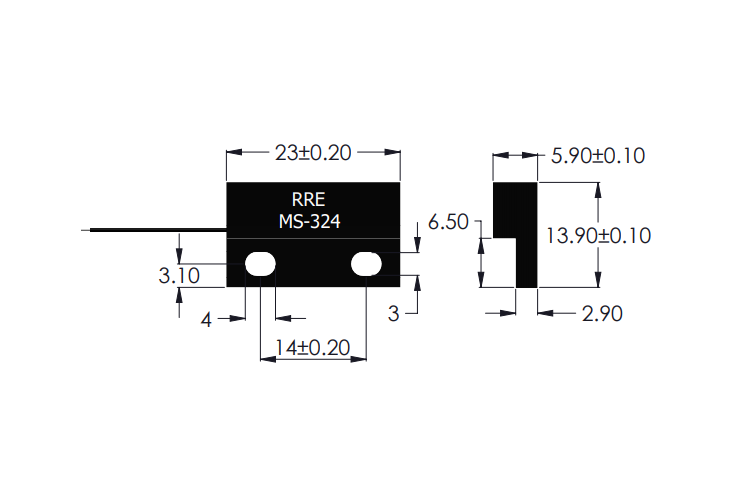

Miniature Flat Pack Reed Sensor MS-324

Features

10W Contact Rating. Normally Open contact. Three sensitivity bands. Sputtered Ruthenium Contact. Higher Shock Limits. Easy Screw Mounting.

Benefits

Omni-polar. Does not require power for operation. RoHS Compliant. Not ESD Sensitive. Various Cables and Connectors Available. Actuator with same Housing available.

📝Description

This miniature flat pack sensor is designed for robust industrial applications, offering the convenience of M3 screw mounting capability while reliably switching moderate loads of up to 10W. Its adaptability makes it particularly suitable for environments where fine distance adjustments are necessary. Depending on the type of magnet and AT band selected, the sensor provides various activating distances, ensuring flexibility to meet specific operational requirements.

For enhanced versatility, this miniature flat pack sensor can be customized with non-standard connectors upon request, accommodating unique integration needs in diverse industrial settings. Prior to shipping, each sensor undergoes rigorous 100% testing to validate its performance across critical parameters including Operate AT, Release AT, Static Contact Resistance, and Variable Contact Resistance. This meticulous testing process ensures that every sensor meets stringent quality standards, delivering consistent and reliable performance in demanding applications.

As an omni-polar device, the sensor responds to magnetic fields from both north and south poles, offering flexibility in magnet orientation. Engineers can optimise its operation by selecting the appropriate AT band, magnet strength, and operating axis.

In specialized applications such as those requiring secure mounting and dependable switching in industrial machinery, HVAC systems, or automotive components, this sensor’s durable construction and configurable features make it an ideal choice. Its ability to withstand challenging environments while maintaining consistent performance underscores its suitability for critical electronic and mechanical applications where reliability and adaptability are paramount.

Magnets for Actuating Reed Switches and Reed Sensors

|

Drawing of Cylindrical MagnetsDrawing of Rectangular Bar Magnets starFeaturesNdFeB High Energy. Nickel coated. Energized

Continue reading

Sep 3, 2024 |

Actuation Distances for MS-324 Flat Pack Sensor

|

Operate and release distances for the MS-324 miniature Flat pack sensor in the three standard AT bands when actuated (as shown in the

Continue reading

Sep 3, 2024 |

⚡️Electrical

| Contact Form | A | |

| Contact Rating (max) | W/VA | 10.0 |

| Switching Current (max) | A | 0.5 |

| Carry Current (max) | A | 1.50 |

| DC Switching Voltage (max) | VDC | 180 |

| Breakdown Voltage (min) | VDC | 200 |

| Contact Resistance (max) | mΩ | 150 |

| Insulation Resistance (min) | Ω | 109 |

| Capacitance (typ) | pF | 0.2 |

📊Miscellaneous

| Operate Time (max) | ms | 0.35 |

| Bounce Time (max) | ms | 0.30 |

| Release Time (max) | ms | 0.15 |

| Resonance Frequency (typ) | Hz | >2000 |

| Operating Frequency (max) | Hz | 500 |

| Operating Temperature Range | °C | -40 to +70 |

| Shock Resistance (½Sin wave for 11ms) | G | 50 |

| Vibration Resistance (10-2000 Hz) | G | 20 |

⚙️Ordering Code

MS-324-(Operate Band Code)-(Cable Length in mm)-(Cable Termination Code)

| Operate Band Code | ||

| 1 | AT | 10-15 |

| 2 | AT | 15-20 |

| 3 | AT | 20-25 |

| Cable Termination Code | Termination Type |

| S | Stripped to 5.0 mm |

| T | Stripped and Tinned |

Example :MS-324-1-500-S Denotes MS-324 Flat-pack Sensor in 10-15 Operate Band (AT), with 500 mm cable length and Stripped to 5 mm.

Other Special Configurations: Lower Static Contact Resistance, Dynamic Contact Resistance Limit, Special Release Limits.

🛠️Usage Notes

Here are some of the recommended usage notes to ensure maximum durability of this product. The complete usage notes are available here.

Ampere Turn Selection for your Application

|

Selecting the appropriate Ampere Turn (AT) or magnetic sensitivity for a Reed Switch, Reed Sensor, or Magnet Sensor is crucial in any

Continue reading

Jul 24, 2024 |

Effects of Temperature on Reed Switches and Magnets

|

The typical operating temperature range for reed contacts spans from -40°C to +200°C, but abrupt temperature changes can potentially

Continue reading

Jul 24, 2024 |

Handling of Reed Switches

|

Handling of Reed Switches Reed Switches, Reed Sensors, and Magnet Sensors are delicate devices prone to developing micro cracks in

Continue reading

Jun 17, 2024 |

Ferro-magnetic Parts

|

Reed Switches utilize a nickel-iron alloy, sputter coated with additional Ruthenium to render it ferromagnetic while maintaining low

Continue reading

Jun 17, 2024 |

Cable Handling

|

Magnet Sensor Cable Handling When integrating Reed Switches soldered to cables or using off-the-shelf Magnet Sensors with cables,

Continue reading

Jun 17, 2024 |

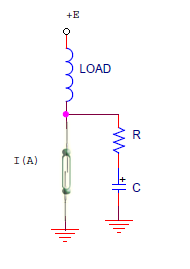

Protection Circuits for Reed Switches

|

It is assumed that the ideal reed switch load is a Resistive Load, but it is almost impossible to reduce any load to purely resistive.

Continue reading

Jun 17, 2024 |

🧰Applications

Although we can never restrict the use of a reed sensor to a particular field, the following is a list of some of the applications that the MS-324 Magnet Sensor is known to perform well.

Pet Door Monitoring Using Magnet Sensors

|

For many pet owners, one of the daily inconveniences is having to constantly open and close the door to let pets outside to do their

Continue reading

Jul 8, 2025 |

Gas Stoves and Cooking Ranges Use Reed Sensors for Ignition

|

Kitchen safety is of utmost importance, especially when working with gas stoves and cooking ranges. Gas leaks and malfunctions can lead

Continue reading

Oct 13, 2024 |

Surveyor’s Wheel Uses Reed Switches for Distance Measurement

|

A Surveyor's Wheel, also known as a Trundle Wheel, serves as a fundamental tool for measuring distances efficiently. Designed with

Continue reading

Sep 3, 2024 |

Welding Machines Use Magnet Sensors to detect Current Flow

|

Welding machines come in two main types: Constant Current and Constant Voltage. In Constant Current welding machines, the output voltage

Continue reading

Sep 3, 2024 |

Model Trains Use Reed Switches to change Signals

|

Model trains have evolved into a meticulous hobby where enthusiasts recreate historical locations and periods with astonishing detail and

Continue reading

Sep 3, 2024 |

Blowers Use Reed Switches to detect drop in Flow-rate

|

Blowers, also known as centrifugal fans, find extensive application across various fields for air or gas movement, serving purposes

Continue reading

Sep 3, 2024 |

Door and Window Security in Smart Homes Using Magnet Sensors

|

Ensuring the security of doors and windows is paramount for homeowners, both when they are away and when they are at home. In modern

Continue reading

Sep 3, 2024 |

Rowing Electronics Data Tracking Using Reed Sensors

|

Rowing electronics have revolutionized the way rowing data is tracked and utilized, not only in competitive rowing but also in the realm

Continue reading

Sep 3, 2024 |

Seat belt lock sensing Using Reed Sensors

|

Seat belts serve as crucial safety devices in vehicles, protecting occupants from potentially harmful movements during collisions or

Continue reading

Sep 3, 2024 |

Airbag deployment Using Reed Switch based Seat Sensors

|

Modern vehicles are equipped with sophisticated airbag systems designed to deploy rapidly and deflate quickly during collisions or rapid

Continue reading

Sep 3, 2024 |

Reed switches for Door sensing on Copiers and Scanners

|

Paper Scanners or Copiers, are devices that use an optical head to scan images or printed documents. The most commonly used model is a

Continue reading

Sep 3, 2024 |